In the professional door hardware industry, the mortise lockset is regarded as the pinnacle of security and durability. Unlike standard residential hardware, a mortise lock requires a rectangular pocket—or mortise—to be precisely machined into the door edge. This design enables a larger, more complex internal mechanism that can withstand the high-frequency use typical of commercial, institutional, and industrial environments.

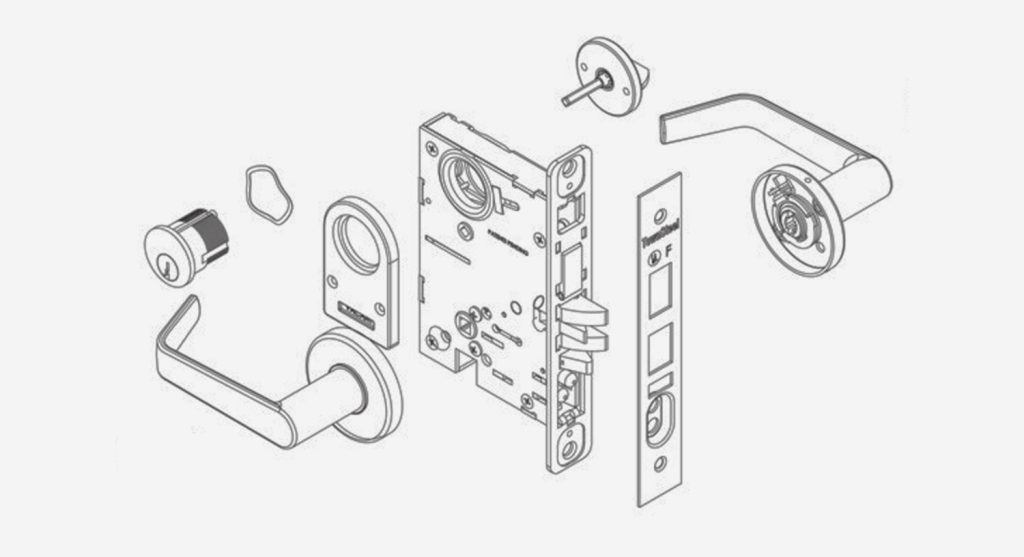

To fully appreciate the system’s strengths, it’s worth examining the internal mortise lock components. Its primary element is the lock case, a heavy-duty steel housing that contains the latch bolt, stop works, and deadbolt.

Unlike cylindrical locks, a mortise chassis often integrates both the latch and a secondary deadbolt within a single unit. This is controlled by a threaded mortise cylinder that provides superior resistance to physical bypass attempts. The lever or knob trim is then connected through the door via a spindle, ensuring that the structural integrity of the lock remains independent of the exterior trim.

When evaluating mortise vs cylindrical lockset options, the primary differentiator is structural stability. A large bore-hole is used to install cylindrical locks, which may weaken the door’s cover over time.

Meanwhile, mortise locks are recessed into the door frame and protected by surrounding steel or wood.

Mortise locks are designed for Grade 1 high-traffic zones. Meanwhile, cylindrical locks are ideal for light-medium traffic. The former offer more versatile features, such as hotel privacy or classroom security, which are typically absent in standard cylindrical formats.

Distributors and door closer business owners must adhere to commercial mortise lock standards. It’s non-negotiable for project compliance. The standard used must be ANSI/BHMA A156.13, which classifies locks by life cycle and security strength.

The testing process for Grade 1 mortise locks must demonstrate that they can withstand over 1,000,000 cycles. Also, during testing, such a lock must resist heavy impact and prying and verify structural integrity under forced-entry conditions. Also, they must be UL 10C certified to ensure the latch is fully engaged even under extreme thermal expansion during fire.

The complexity of a mortise lock installation requires specialized tools, such as a mortise jig, to ensure the pocket is square and centered. Because the lock case is large, door hardware compatibility must be verified during the submittal phase.

The factory ‘preps’ the standard hollow metal door with a reinforced internal box to accept the lock. For those retrofitting an existing opening, the backseat (approximately 2-3/4″) and door thickness (typically 1-3/4″) must align with the chosen hardware. This prevents compromising the fire rating or any structural warranty of the door leaf.

A mortise lockset represents a significant investment in facility security. The combination of high-cycle durability with robust mortise lock components reduces long-term maintenance costs. Whether you are making a mortise vs cylindrical lockset decision or ensuring door hardware compatibility, prioritizing commercial mortise lock standards helps provide an accessible and safe entryway.