In commercial hardware specifications, selecting the appropriate door closer is a matter of liability, fire code compliance, and asset protection. For B2B procurement officers and distributors, the primary technical objective is to match the closing force to the specific structural requirements of the opening. This guide provides the engineering parameters necessary for professional installation and maintenance.

The closing force is the torque generated by the closer to overcome air pressure and latch friction. Under EN 1154, this is quantified using Power Sizes 1 through 6. Specifying an incorrect size increases wear on the pivot points and may void fire safety certifications.

Using an undersized closer results in incomplete closing, while an oversized unit makes the door difficult to open, potentially violating accessibility laws such as the ADA. To ensure precision, technical teams must analyze the door leaf width and mass before finalizing the hardware schedule.

Distributors must reference a door weight vs closing force chart to ensure the hardware meets the mechanical demands of the installation environment:

| Power Size | Max Door Mass | Door Leaf Width | Recommended Application |

| EN 2 | 40 kg | 850 mm | Interior Office Doors |

| EN 3 | 60 kg | 950 mm | Standard Commercial Fire Doors |

| EN 4 | 80 kg | 1100 mm | High-Traffic Entrance Doors |

| EN 5 | 100 kg | 1250 mm | Heavy-Duty Industrial Doors |

For external openings or buildings with high HVAC-induced stack pressure, hardware should be “sized up” to ensure the closing force remains sufficient to secure the building envelope against wind loads and internal suction.

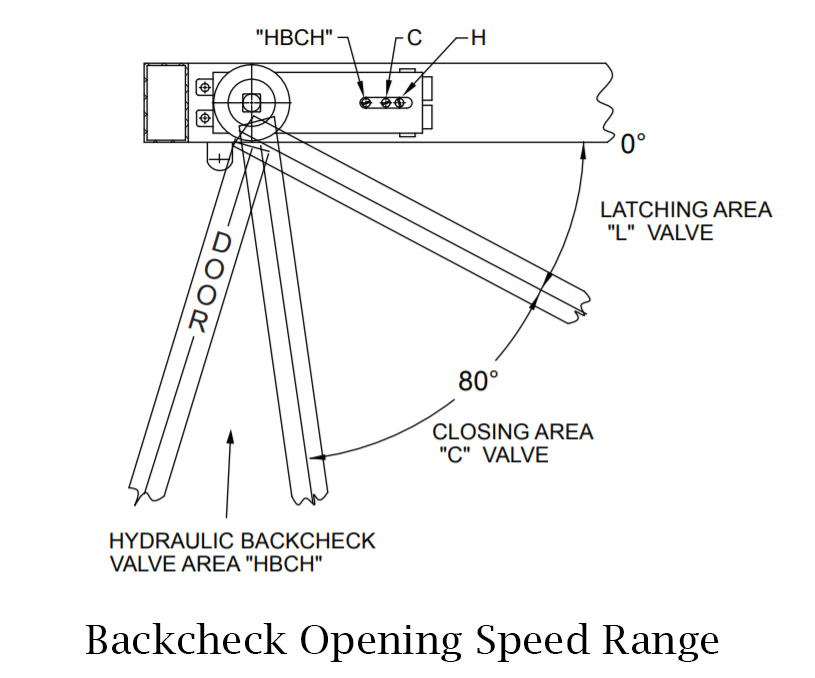

The closing speed adjustment allows the ‘sweep’ range from 180° to 15°. A hydraulic valve regulates this phase by controlling the cylinder’s internal oil flow. When the valve turns clockwise, hydraulic resistance increases, slowing the door’s travel.

During the final 10-15° cycle, the latching speed setting controls it. Achieving this is vital to ensure the latch bolt engages the strike plate, especially in smoke-sealed or pressurized environments.

If the latch speed is inadequate, unsecured openings are expected. Also, excessive speeds will cause mechanical shock to the frame and hinges. Overall, precision tuning of the valve ensures the door secures firmly without compromising the hardware’s structural integrity.

Professional-grade closers often feature additional valves for complex architectural requirements:

Mastering closing force is essential for maintaining building security and user safety. For distributors, providing clients with the correct door weight vs closing force specifications and precise closing speed adjustment guidance is key to reducing site callbacks and ensuring long-term project success. Proper hardware selection minimizes maintenance overhead and guarantees that fire-rated openings perform reliably under heavy-duty cycles.