Door closer grades matter when specifying hardware for residential or commercial projects. It’s among the primary indicators of its long-term performance. At first glance, the two closers in different grades appear identical but differ in their internal engineering. Before sourcing the hardware, it’s essential to understand the door closer Grade 3 vs Grade 1 features. This allows procurement teams to assess upfront costs and ensure they’re sourcing the appropriate door-closer grade levels for clients.

The main distinction of these door closer grades is the cycle count. This refers to the number of times a door closer can open and close while maintaining at least 60% of its original efficiency. The classification is done by the Builders Hardware Manufacturers Association (BHMA) and the American National Standards Institute (ANSI) based on extensive destructive testing.

Essentially, upfront costs for Grade 1 door closers are higher than Grade 3. However, a Grade 1 closer provides four times the lifespan of a Grade 3 unit. This significant long-term value stems from the Grade 1’s superior hydraulic engineering and its use of an all-weather fluid that resists thickening or thinning across extreme temperature ranges.

Grade 1 closers have four times the lifespan of Grade 3 variants. This difference in longevity stems from the excellent hydraulic engineering and the use of an all-weather fluid that resists thickening in cold temperatures and thinning in extreme heat.

When you factor in the cost of the replacement hardware, the labor for a second installation, and the operational downtime of a broken door, the Grade 1 unit consistently offers a lower Total Cost of Ownership. For developers looking at bulk procurement, investing in door closer grade 1/3 systems based on traffic data often simplifies maintenance schedules and reduces the “cost per unit” over the building’s 10-year financial horizon.

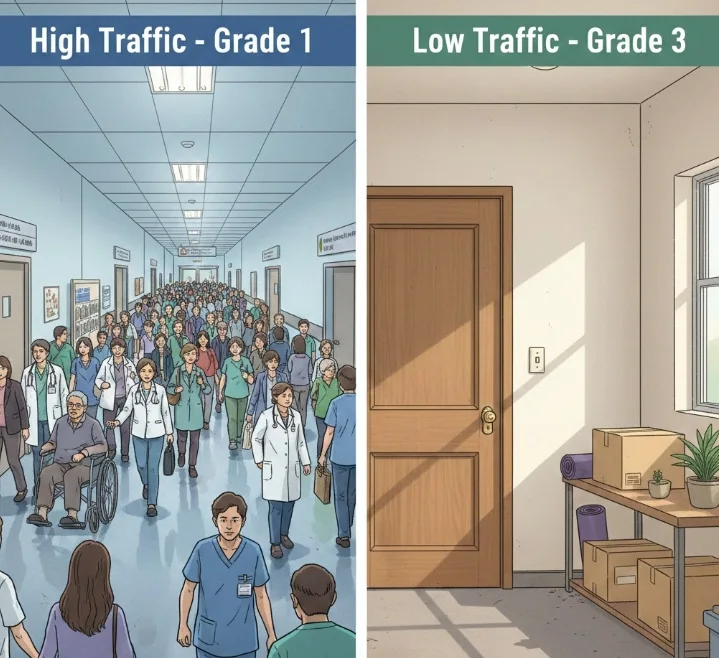

Choosing between door closer Grade 1/3 depends on various factors, including the high traffic volume and the door’s environmental demands. It’s ideal for hospital corridors, school hallways, and main entrances to use Grade 1 door closers. They are designed with forged steel arms and high-nitrile seals to withstand high-volume traffic, potential physical abuse, and stack pressure from HVAC systems.

On the other hand, lower-traffic zones such as mechanical rooms, individual apartments, and storage closets can use Grade 3 door closers. In most cases, the hardware might only see a dozen cycles per week. Given this traffic volume, Grade 3 units can deliver years of reliable performance.

Another key aspect of door closer grades is the level of control offered to the facility manager. Grade 1 closers usually feature independent valves for sweep speed, latch speed, and backcheck. The backcheck feature is especially vital in Grade 1 environments, as it prevents the door from being thrown open into a wall, thereby protecting both the hardware and the building structure. Grade 3 closers may offer limited adjustment, often combining sweep and latch speeds or omitting backcheck entirely.

Commercial projects will most likely use Grade1 door closers. This protects building owners from costly replacement cycles. At the same time, this quality ensures the hardware complies with fire safety codes and ADA standards. By identifying door closer grades and matching them to every space’s expected traffic, it creates a hardware schedule that is cost-effective and functional.