Maintenance on most commercial facilities, such as doors, is non-negotiable. However, the frequency varies by context. The stains on the door closer are most likely the result of time spent in the building’s entryway.

A door closer leaking oil indicates that the system designed to ensure safety, accessibility, and fire containment is compromised. But do facility managers go straight to replacing the closer, or repair it? Read through the succeeding section to know more.

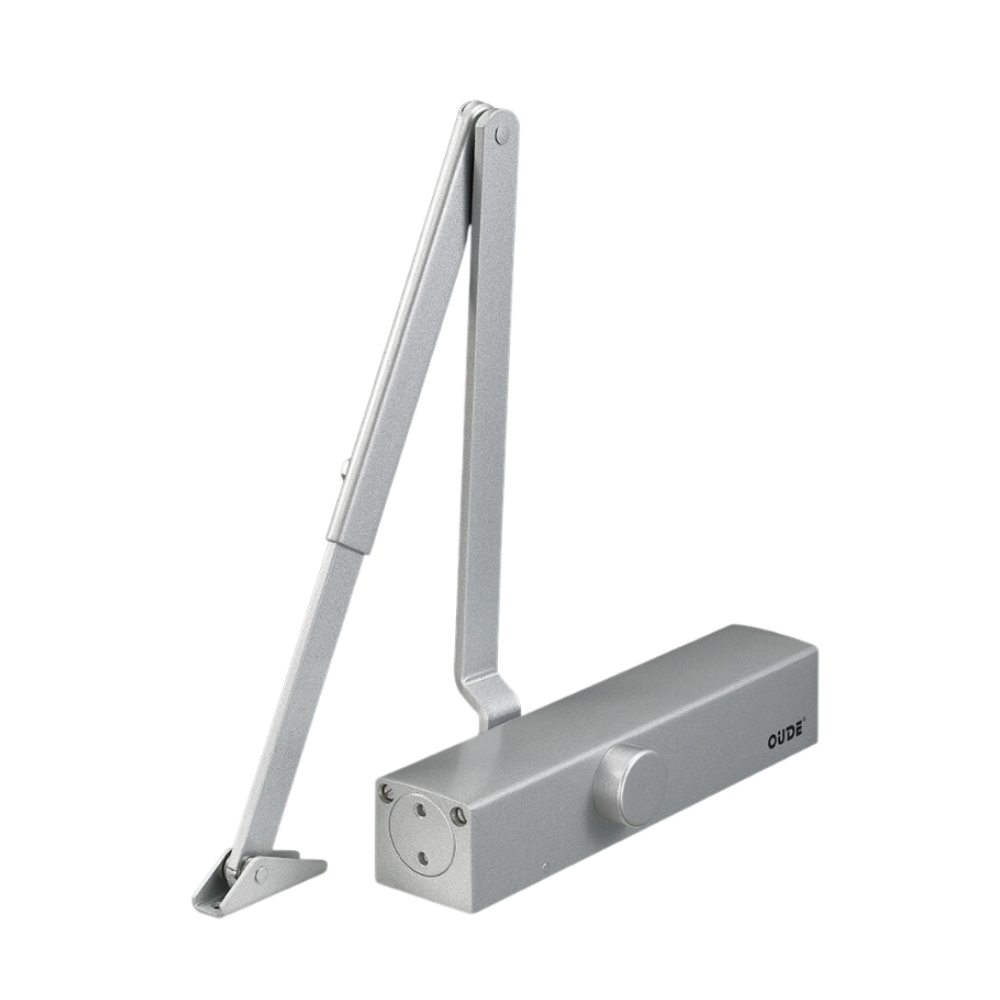

Identifying a failing unit early can prevent structural damage to the door and frame. There are three obvious patterns that indicate that the hydraulic door closer is losing its internal door closer fluid:

A door closer is designed to be a silent, controlled operator. When a door closer leaking oil reaches its threshold, its mechanical behavior changes. You may notice the door “slamming” during the final few inches of the closing cycle. The lack of a door closer fluid to provide resistance causes the spring to take over, accelerating the door dangerously.

It’s even more dangerous on fire-rated doors. They’re expected to be latched to keep the smoke from spreading. If the valve is constantly adjusted due to inconsistent speeds, the hydraulic closer is failing to maintain a steady pressure.

Once a leak is confirmed, facility managers must decide between a repair kit and a full unit replacement. While “re-sealing” a closer was common decades ago, modern commercial reality usually favors replacement for several technical reasons.

While a seal replacement is possible when the cylinder becomes scratched, it’s still temporary. Eventually, the new seal will be shredded by metal fragments. This makes replacement not a cost-effective option. Also, labor costs, which include disassembly, cleaning, replacement, and fluid refilling, can be higher than sourcing a new, factory-certified unit.

In most cases, repaired door closers don’t have a warranty. Unlike new units that come with multi-year mechanical warranties, and the assurance that the device meets ANSI Grade 1 safety standards.

To avoid the “repair or replace” dilemma, procurement should focus on seal quality. High-quality closers use high-nitrile seals engineered to withstand friction from millions of cycles. Furthermore, using all-weather door closer fluid helps maintain internal pressure, preventing the “seal-blowing” surges that occur when cheap oil thickens in winter and thins in summer.

While the door closer leaking oil might still technically move, it’s no longer reliable and may compromise life-safety functions. Most commercial spaces prefer a safe, cost-effective solution: replace the leaking unit with a quality-standard hydraulic door closer. It prevents property damage and guarantees full compliance with fire and accessibility codes.