There is technically a thorough process in procuring door closers for steel doors. While the right supplier is crucial, buyers must first consider the sizing of such doors to ensure the safety and functionality of commercial spaces. Here lies the essence of a door closer size chart for a precise calculation. This guide helps you identify the key points a buyer should review when using such a size chart.

The fundamental principle behind door control is the equilibrium between the door weight vs closing force. Commercial steel doors usually weigh 100-150 lb, meaning they’re denser than wood- or aluminum-made doors. A very low closing force causes the building to fail under the air pressure, making it unsecured.

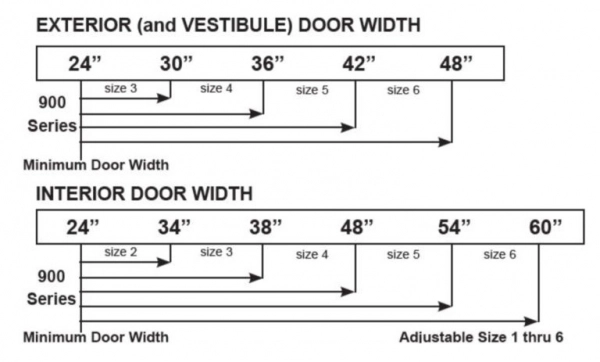

In contrast, an excessive closing force makes steel doors a physical barrier. This will be an issue when complying with the Americans with Disabilities Act (ADA) standards. It requires interior doors to be open with no more than 5lb of force. If you base it on the door closer size chart, the ‘Power Size’ (around sizes 1 to 6) must be used to achieve balance.

To use a sizing chart effectively, you must follow a structured technical process to obtain precise door closer measurements. Miscalculating even one aspect can lead to premature hardware failure or safety violations.

When reading a manufacturer’s door closer size chart, look beyond the basic numbers to identify these specific performance aspects:

Because steel doors are subject to environmental changes, fixed-size closers are often a liability. Modern engineering solutions offer adjustable power ranges. This adjustability is vital for steel doors because it allows for seasonal tuning. In the winter, thicker air and heavier grease in the hinges may require a slight increase in power, which can be managed by referencing the manufacturer’s adjustment turns against the door closer size chart.