Having trouble with your door closers? A commercial door closer is easy to adjust once you know which valves control the door’s speed, latching, and opening resistance. In most cases, you’ll fine-tune the sweep, latch, and backcheck valves in small increments and, if needed, reposition the arm so it sits at the correct angle.

This guide walks you through a simple, six-step process to adjust a commercial door closer arm safely and effectively.

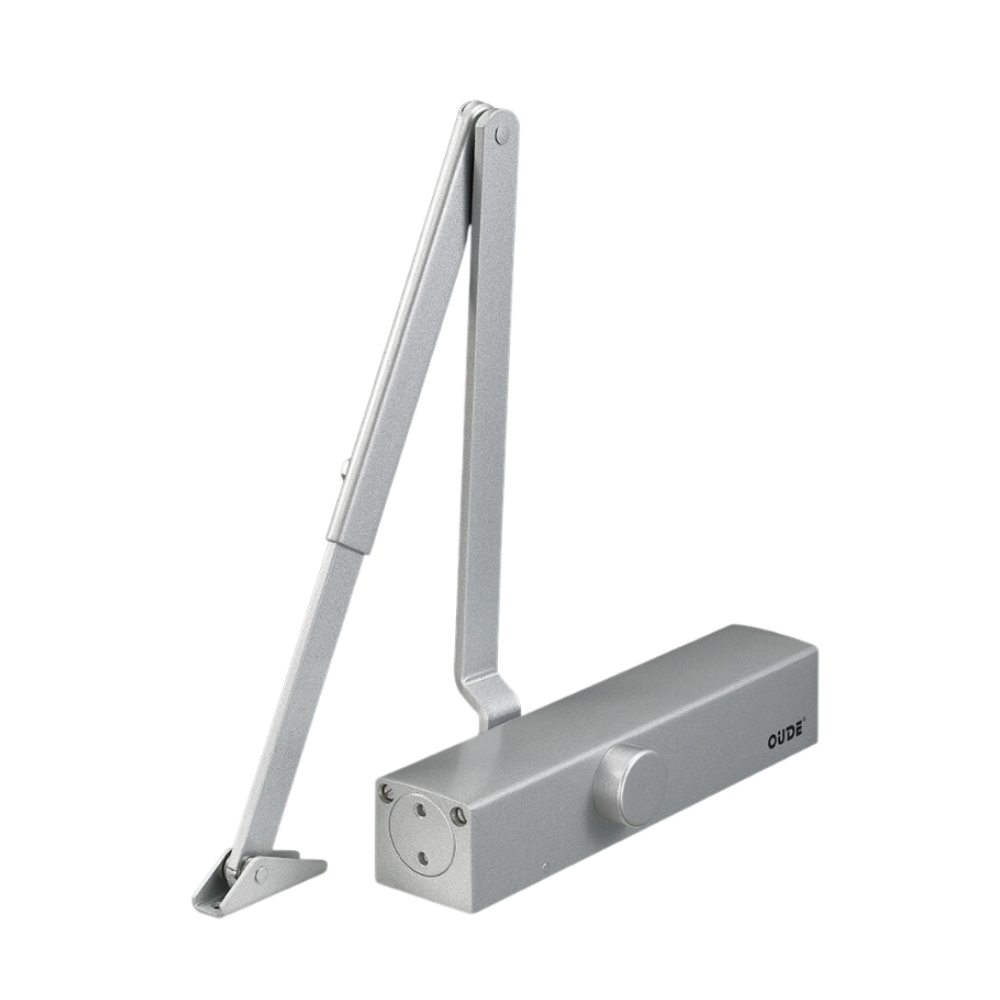

Before making any adjustments, it’s important to understand the door closer arm types and the location of key control points. Most commercial closers have a regular arm, a parallel arm, or a top-jam arm, and each type affects how the door moves and how the arm should be positioned.

To find out the type of door door closer arm you have, remove the closer cover of the control valves which usually include the sweep speed, latch speed, and, on many models, a backcheck valve.

Then, inspect the door closer alignment before touching any screws. The arm should sit roughly perpendicular to the door when it is fully closed, with no twisting, bending, or obvious looseness.

If the arm is out of position, loosen the clamping screw, reposition it on the spindle, and retighten. This will make subsequent commercial door closer adjustment of the sweep, latch, and backcheck much more effective and reduce wear on the mechanism.

Next, you will need to make sure that you are adjusting your door closer arm from a neutral position to prevent overcorrection. Do this by turning the sweep, latch, and backcheck valves clockwise until they stop.

The sweep controls most of the door’s closing arc, from fully open to about 10–15 degrees from the frame. If the door closes too quickly or too slowly, adjust the sweep screw in small ¼-turn (90 degree) increments. Turn it clockwise to slow the door or counterclockwise to speed it up. Make sure to test the door and repeat as needed after each adjustment.

The latch speed controls the final few inches of the door’s closing cycle. Fine-tuning the latch ensures that the door closes quietly, engages securely, and meets safety requirements. If the door closes fully but fails to latch, increase the latch speed slightly. If it slams into the frame, reduce the speed by turning the screw clockwise.

The backcheck slows the door as it approaches its fully open position, preventing it from hitting the wall or frame.

To adjust, start by turning the backcheck valve about 1¼–1½ turns counterclockwise. Open the door slowly and watch its motion: it should come to a steady stop, and around 75 degrees it should begin to slow so it doesn’t slam or get caught by wind. Turning the valve counterclockwise allows the door to open a little wider, while clockwise reduces the opening range.

A commercial door closer works only as well as its arm is calibrated. If the door slams, won’t latch, drifts open, or closes too slowly, the closer arm is almost always the first place to check.