Workspaces and professional environments usually experience echoing thuds from heavy doors slamming shut. Annoyance will be the primary reaction. However, consistent thuds also indicate that the entryway should be inspected, especially since it used to operate silently and smoothly.

There is likely a ‘runaway’ door closer, which must be addressed. Restoring safety and silence requires a clear understanding of the mechanics behind door closer adjustment screws and the critical role of door closer latch speed.

The door closer consists of a heavy-duty spring that stores mechanical energy to pull the door shut, while the hydraulic fluid serves as the brake. These two enable controlled movement in the entryway. If the door constantly slams, there’s surely an issue with the brake and the spring.

There are several reasons this happens. First, the timing of fluid flow within the internal components is not properly calibrated. Second, there might be fluid leaks in the chamber. The absence of fluid on the closer leaves the spring to snap the door shut. In short, door slams are more of a hydraulic concern than a spring issue.

With hydraulic fluid being temperature-sensitive, the oil in the door closer is expected to thin out in hot summers, reducing viscosity. The thinner oil is likely to flow through internal valves faster than usual, which reduces the braking force. In the winter months, the oil thickens, causing the door to move so slowly that it fails to latch.

The frequent manual door closer adjustment screws on the door indicate low-quality hardware. High-quality ones can address this issue by using an all-weather fluid on the closer. This type of fluid ensures a consistent thickness across changing environments.

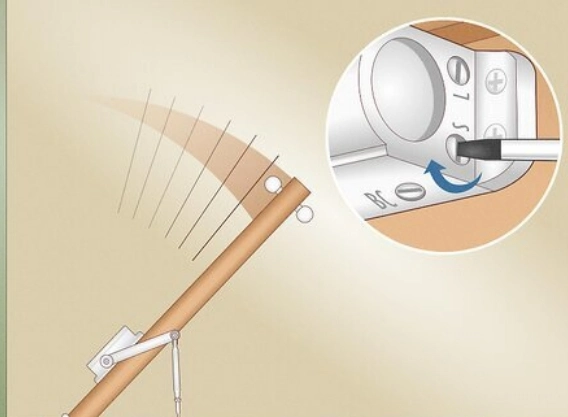

Most modern commercial units are equipped with adjustable valves that let you fine-tune the door’s behavior. These valves are regulated by small screws usually located on the end or side of the closer body, often hidden under a plastic or metal cover.

In high-volume spaces with doors that see hundreds of cycles per day, manual adjustments are not sustainable. The only long-term solution is to install an anti slam door closer. It’s engineered with precision-machined internal components that deliver stability that standard hardware cannot match.

The primary advantage of a dedicated anti slam door closer is its ability to maintain “valve memory.” Cheaper variants will cause adjustment screws to loosen over time. Meanwhile, premium-quality anti slam closers are designed to keep the fluid exactly where it belongs, thanks to their high-nitrile seals. Once the door closer latch speed is set, it will remain unchanged for millions of cycles.

There is a point where no amount of turning the door closer adjustment screws will fix the problem. The internal seals have failed if there is oily residue on the closer body or oil leaks on the floor, making the ‘brake’ nonexistent. Because these units are factory-sealed under pressure, they cannot be reliably refilled in the field.

Tightening the leaking door closer is useless. The air pockets created by the missing fluid cause inconsistent door movement. It can either stick or slam, which is not typical behavior for a functional door. For buildings that prioritize ADA compliance and visitor safety, it’s essential that leaking units be replaced immediately. Continuously using leaking closers will degrade the hinges and door frame. This may lead to expensive maintenance and repairs in the future.

Fixing slamming doors is more than just eliminating noise; it’s about protecting structural investments and the individuals who use them. Understanding the purpose of door closer adjustment screws and calibrating the door closer latch speed for a gentle door closure extends the hardware’s lifespan. But in situations when there’s constant leaking on the closers, the most cost-effective solution is to use a Grade 1 anti-slam door closer.