Among the most critical components of a safe and efficient shopping mall are its doors. Ensuring safety and convenience is a priority. To do so, these doors must use the best heavy duty commercial door closer. There are generally thousands of foot traffic daily in most shopping malls, which can cause mechanical strain on doors. This is why choosing the right one is essential.

This guide addresses the technical parameters of hardware that can withstand unique strains in retail environments while preserving its architectural intent.

The mall’s architectural style often dictates the type of closer required. The following configurations are commonly used.

Finding the right door closer supplier can be challenging. Every shopping mall or client has different hardware requirements that must be addressed before selecting a supplier. The following are some vital factors to examine closely.

Shopping malls present a unique challenge for door control. Unlike smaller office settings, where usage is predictable, mall entrances face constant, irregular cycles and varying wind loads. One of the most significant technical hurdles is “stack pressure”—the pressure difference between the building’s interior and exterior, driven by HVAC systems and open atriums.

In these high-pressure scenarios, standard hardware often fails within weeks. Engineers must prioritize hardware rated for extreme durability. A heavy duty commercial door closer is specifically designed to provide:

Compliance with ANSI/BHMA A156.4 is non-negotiable, whether it’s about operating a high-end boutique or a regular shopping mall. It separates residential-grade hardware from true industrial components. For shopping malls, Grade 1 is the only acceptable rating because it is certified for 2,000,000 cycles.

While it’s true that the Grade 1 can be a little more expensive, the Lifecycle Cost Analysis (LCCA) that it’s generally more cost-effective over time.

Consider a mall entrance seeing 2,000 cycles per day: a Grade 3 unit (rated for 500,000 cycles) reaches its mechanical fatigue limit in less than nine months. By contrast, a Grade 1 unit provides years of service. This effectively lowers the Total Cost of Ownership (TCO) by reducing replacement frequency, minimizing storefront downtime, and slashing labor costs associated with repeated high traffic door maintenance calls.

Well-manufactured door closers feature all-weather hydraulic technology to ensure consistent viscosity from -40°C to 80°C. Without sufficient thermal stability, as the ambient temperature rises and the fluid thins, the worst-case scenario is that the door closer won’t latch.

With precision hardware, maintenance personnel can make minor adjustments via specific valves rather than overhauling the entire system. The Sweep Speed and Speed valves are checked regularly. The former controls the door from full open to about 10 degrees, while the latter controls the final inches of closing, ensuring a secure lock.

The interior opening force in shopping malls must not exceed 5lb. Most manufacturers have the rack-and-pinion design to achieve the desired opening force. This ensures the door can latch under wind pressure. A heavy duty commercial door closer from a trusted supplier offers convenience for the elderly, children, and people with disabilities.

It’s also important to consider controlled closing for safety. If the doors close too quickly, it may strike customers. At the same time, the backcheck function is vital, preventing the door from being projectile in high winds, as it could rip the hinges out of the door frame.

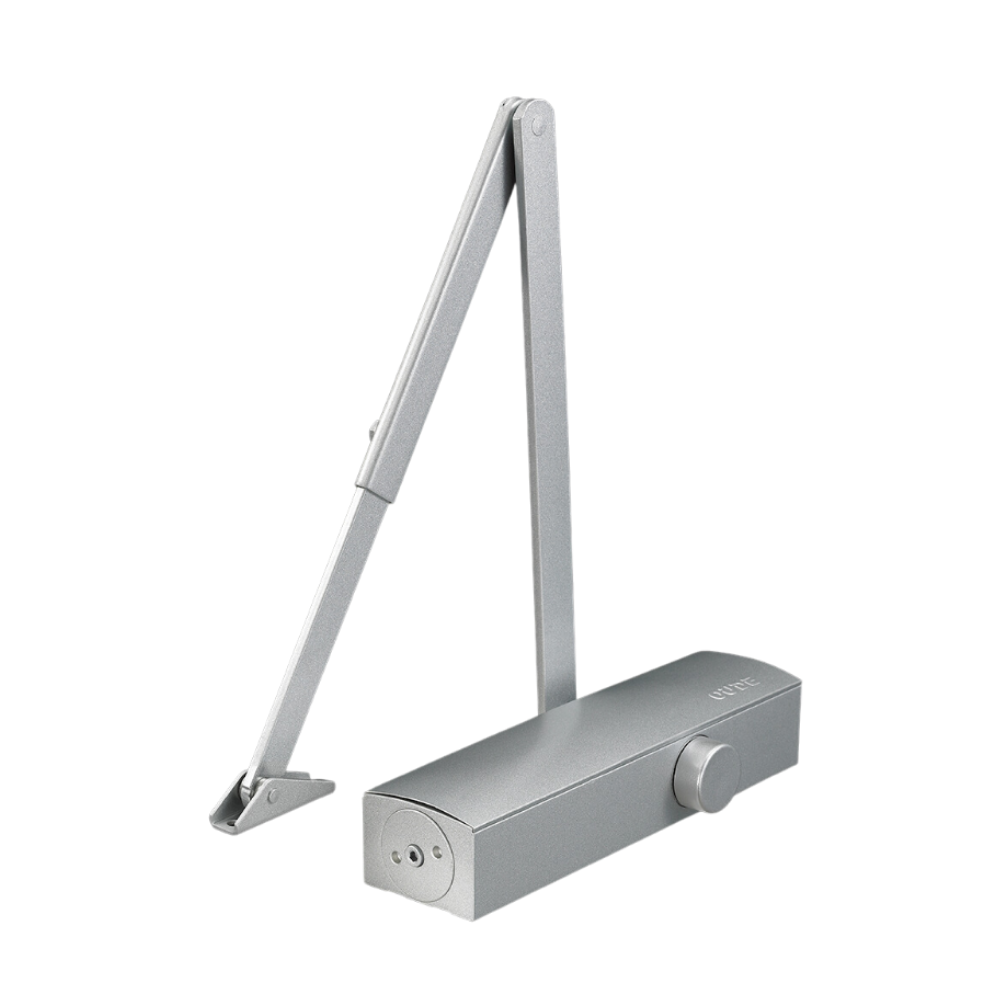

When evaluating commercial door closer brands, engineers look for specific manufacturing hallmarks. High-quality closers typically feature alloy aluminum die-casting housings and forged steel arms. These materials are selected to resist structural degradation and hydraulic failure across millions of operations.

Investing in a premium-quality, heavy duty commercial door closer for shopping malls benefits both the owner and its customers. During the selection process, it’s also critical to ensure the hardware matches the store’s door material and foot traffic. This results in an improved customer experience.

Quality hardware is often UL 10C listed, verifying that the mechanism maintains its latching force during a fire event. By specifying a closer that meets ANSI Grade 1 standards, facility managers protect their design investment and ensure public safety.