The contemporary architecture landscape has shifted from the ‘black-out’ hardware niche aesthetic to an industry standard. Surely, the black door closer offers excellent visual appeal to minimalists and industrial designers; however, a surface-level selection is not enough.

Facility managers sometimes face challenges sourcing hardware that delivers a matte-black finish without compromising mechanical integrity. The best quality of a black door closer is its durable coating and precise internal hydraulics. More than these qualities, it’s also necessary to look closely at the essential features of such door closers.

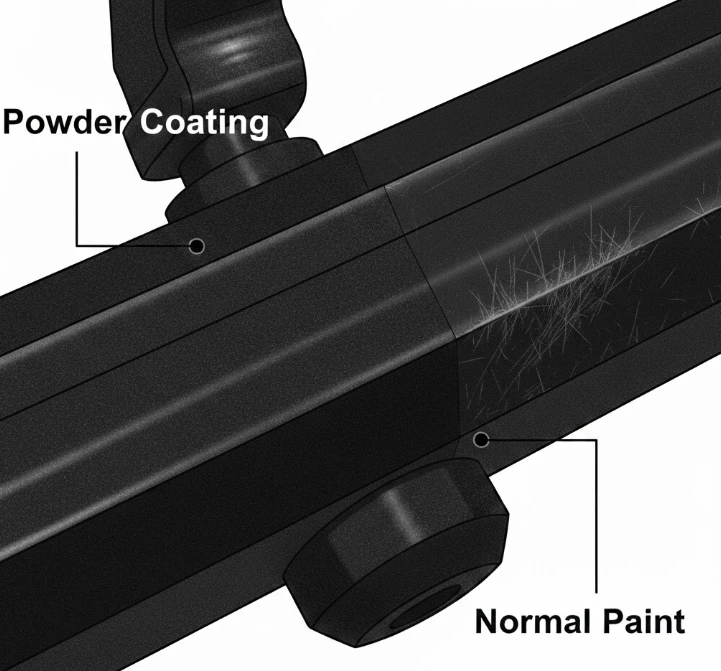

One of the most common issues with a low-quality black-finished door closer is chipping in high-friction areas. During the procurement process, managers must distinguish between the standard wet-paint finish and high-performance power coatings.

Industrial-grade hardware is finished with an elastostatic powder coating process. This will serve as a reliable barrier against acidic residues commonly found in cleaning agents. Black door closer manufacturers must also guarantee that the finish passes the 240-hour salt spray test. As a result, the hardware’s aesthetics remain consistent in high-humidity environments.

Modern office designs must use a black door closer evaluated by ANSI/BHMA Grade, not just its profile. For procurements intended for a bustling professional environment, the hardware must be Grade 1 certified. This ensures the seals and internal springs can withstand 2,000,000 cycles.

Look for models that demonstrate such balance – providing a heavy-duty performance, especially for doors of 120kg and being visible in dark, architectural finishes. When internal-alloy aluminum die-casting is combined with high-nitrile seals, the door closer prevents hydraulic leakage, the primary cause of oil stains on black surfaces.

In addition to premium-quality hardware, the product meets specific legal standards without compromising the damping properties. The Americans with Disabilities Act (ADA) requires that office doors must be regularly calibrated to an opening force of up to 5 lbs.

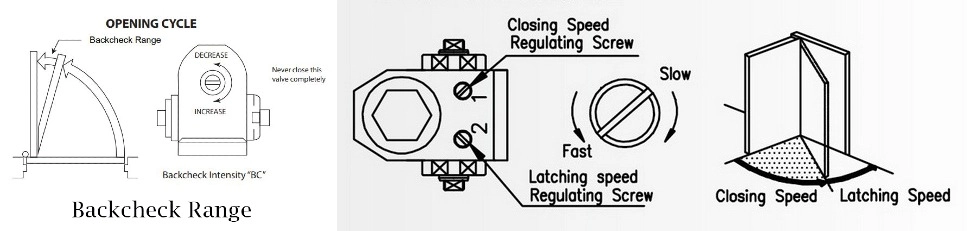

A black door closer must include precision-machined valves to ensure smooth, precise adjustment of latching speed and backcheck. Using these valves on door closers ensures seamless, safe door movement regardless of temperature changes. With stable, all-weather hydraulic hardware, procurement teams can avoid the hassle of seasonal valve tuning. This reduces high operating and maintenance costs while keeping the design’s functional intent.

The ultimate goal of integrating a modern door closer into a high-end office is to have the hardware disappear into the architecture while performing flawlessly. Quality hardware is often accompanied by a UL 10C listing, verifying that the black finish and the underlying mechanism will maintain their latching force during a fire event.

Investing in high-performance black hardware, regardless of the kind of commercial space, is a strategic decision that protects the building’s safety rating and the owner’s design investment. Moving away from economy-grade units prevents the inevitable “finish fatigue” and mechanical failure that lead to premature replacement and mismatched aesthetic results across a floor plan.