High-traffic commercial environments must foster long-term structural integrity. It’s necessary to build a synergy between continuous hinges and door closers. Traditional butt hinges are subject to dynamic stresses from hydraulic closers. This can result in expensive maintenance. For stable, consistent closing performance, heavy-duty continuous hinges must be used as they distribute weight along the frame’s entire length.

This configuration is the industry standard for high-traffic environments. They include retail hubs, hospitals, clinics, and educational institutions. Fine-tuning such components ensures the door operates as a unified system.

Standard hinges concentrate the door’s weight on two or three specific points. As the door closer is added, the closing cycle’s leverage increases metal fatigue at these stress points. The ‘door sag’ will inevitably happen.

It’s where the door’s top section pulls away from the hinge side jamb, resulting in the bottom edge being dragged along the threshold.

Implementing anti-sag door solutions, specifically geared toward continuous gears or pin-and-barrel designs, eliminates this concentrated stress. This ensures the door remains plumb, which is essential for the closer’s latching speed and backcheck functions to operate within manufacturer specifications. A door that remains square in the frame requires less force to close, effectively extending the life of the closer spring and preventing the “slamming” effect common in failing hardware.

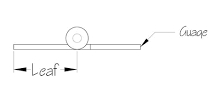

Precise hinge alignment with door closers is a prerequisite for meeting ADA-friendly hinge options and accessibility codes. If there’s a door misalignment of even 3mm, the required opening force may exceed the 5 lb maximum required by ADA standards. Having the exact gap of 1/8″ (3.175mm) between the frame and the indoor door across the vertical span will be made possible through continuous hinges and door closers.

For distributors, offering these systems as a package ensures that clients remain compliant with local building codes. It also provides a barrier-free experience for all occupants, reducing the liability associated with heavy, difficult-to-operate commercial doors.

For industrial distributors, long-span hinge durability is a primary selling point. While pivot hinges require deep drilling and floor preparation, continuous hinges can be easily retrofitted to existing frames. This versatility will be vital for facility managers opting to upgrade their security systems.

This makes them the ideal choice for heavy steel doors or lead-lined high-security entries. In these scenarios, the closer must manage significant mass, and only a full-length hinge can provide the necessary lateral support. The result is a door that feels light to the user despite its massive physical weight, ensuring the closer remains the primary controlling force.

Business owners must prioritize reducing ownership costs by adopting durable engineering. Invest in heavy-duty continuous hinges to eliminate the leading cause of hardware failure, like hinge-side sag. This ensures your continuous hinges and door closers function as a unified, maintenance-free system for millions of cycles. When you prioritize long-span hinge durability and anti-sag door solutions, you guarantee a safer, more efficient entrance that meets both ADA-friendly hinge options and rigorous industrial standards.