Robust and certified door closer range complying with CE and CERTIFIRE standards, ensuring fire resistance and safety in commercial and residential buildings. Multiple models available for varied installation needs.

Explore Product

Different door materials affect installation methods for door closers, requiring tailored approaches for wood, storefront, and metal doors for optimal function.

Door closers can be installed on different door materials—but how we approach that installation varies, depending on the type of material. The differences lie not in the closers themselves, but in the methods and tools required to install them securely and effectively.

Getting the door closer installation right is essential for smooth function and safety. Let’s break it down by each door type and walk through what you need to know.

Here are a few most popular door materials and ideal door closer choice for them:

| Door Type | Key Characteristics | Installation Tips | Recommended Hardware |

| Wood Door | Solid or hollow core, popular in residential and commercial use | Solid core: Use reinforced mounting; Hollow core: Use hollow-door fasteners or sleeve anchors | Screws, hollow-door anchors for hollow doors |

| Storefront Door | Aluminum and glass, commonly used in commercial spaces | Surface-mounted closer; avoid drilling near glass; use self-tapping screws for aluminum | Self-tapping screws, careful placement |

| Metal Door | Durable, used in high-security areas | Mark positions carefully, use self-tapping screws for solid metal, metal anchors for hollow metal | Self-tapping screws, metal anchors for hollow |

Robust and certified door closer range complying with CE and CERTIFIRE standards, ensuring fire resistance and safety in commercial and residential buildings. Multiple models available for varied installation needs.

Explore Product

Wood doors remain a popular choice for both residential and commercial environments, but not all wood doors are the same. The structure and density of the door affect how you approach closer installation.

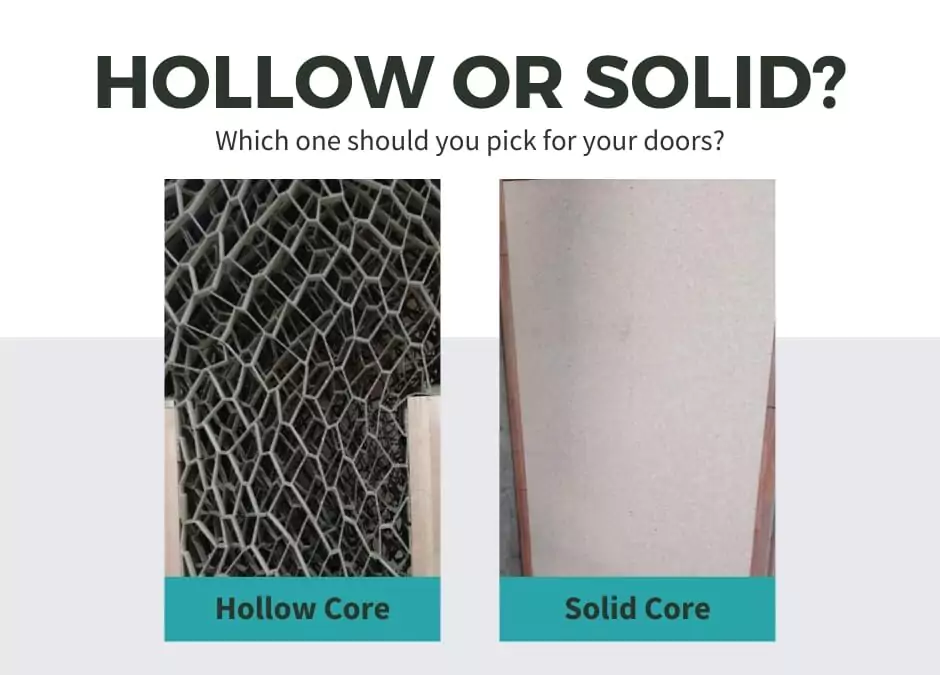

There are two primary types of wood doors that you’re likely to encounter.

Solid Core Wood Doors

Solid core doors are heavy, offering good insulation and noise reduction. Their density makes them more durable and stable when you mount a door closer. You’ll want to ensure that the screws you use can hold the weight and movement of the door long-term. Some installers opt for reinforced mounting plates to secure the closer to such a heavy surface.

Hollow Core Wood Doors

These are lighter and more affordable, commonly found in homes. Installing a door closer on a hollow-core door requires caution. Because they lack internal rigidity, these doors are more prone to damage if you use the wrong screws or don’t reinforce the mounting points. Hollow core doors might require sleeve anchors or specialized hollow-door fasteners to keep your closer secure over time.

When you’re unsure what type of door you have, simply tap on it! Hollow core doors will generally have a hollow, more resonant sound, while solid core doors feel more substantial, with minimal echo.

Common in commercial buildings like retail stores or offices, storefront doors are typically made of aluminum and glass. The frames are usually narrow, so you’ll need a door closer that’s specifically designed for these slim, often frameless constructions. The installation process differs here—particularly because drilling into aluminum can require specialized tools to avoid damage, and you need to avoid the glass areas.

Metal doors are an industry standard in high-security areas like schools, hospitals, and industrial buildings. They’re durable and built to handle heavy traffic. When installing a door closer on a metal door, you typically won’t face the same issues that come with wood or aluminum. However, placement accuracy and using a sharp drill bit for steel or hollow metal doors are essential for a smooth installation. In some cases, self-tapping screws or metal anchors are used to ensure that the door closer remains firmly attached.

When you’re installing a door closer on a wood door, the steps will largely depend on what type of wood door you’re dealing with—solid or hollow.

For solid core doors, a straightforward door closer installation approach works. You’ll begin by marking the position of your closer, usually following the instructions provided by the manufacturer. Pre-drill pilot holes to prevent splitting the wood when you insert the screws.

With hollow core doors, it gets trickier. You’ll still start by marking your spots, but you need hardware designed for hollow doors, such as hollow-core anchors or toggle bolts. These are designed to grip the interior panel without pulling through over time. Use them wherever screws would normally go to ensure a long-lasting door closer installation. Keep the force distributed evenly to avoid warping.

Storefront doorframes often don’t give you a lot of room to work with. You’ll typically use a surface-mounted closer, placed either on the top of the doorframe or on the door itself. With aluminum frames, apply extra care when drilling because they’re easier to dent or damage than steel or wood doors.

Once you’ve positioned the closer, use self-tapping screws designed for metal. These will bite into the aluminum effectively. Additionally, storefront doors often have glass panels running throughout, so you need to pay attention to the mounting process to avoid any cracks or shifts due to pressure on the glass.

Working with metal doors can be straightforward, as the material is sturdy and can handle hefty hardware. Metal doors, particularly hollow metal ones, often have an internal framework designed to support mounted fittings like closers. Here’s how the installation goes:

Always ensure you drill slowly and with control when working with metal. The key is precision—forcing the closer into place can leave you with a misaligned or unstable fixture.

Depending on the type of door—wood, storefront, or metal—the door closer installation can vary in approach and technique. The biggest variable is the material and construction of the door itself, which governs what hardware and methods will work best.

By understanding these differences, you’re not just ensuring the functionality of the door closer but also prolonging the lifespan of both the door and its hardware. Whether you’re working with wood, storefront, or metal doors, attention to detail is critical.

For professional assistance and high-quality door closers, consider Cn-oude. Their expertise and product range can ensure your door closer installation is safe and effective.